-

StevenCHN-TOP çok iyi hizmet sunuyor ve ürünler bize çok yardımcı oluyor

StevenCHN-TOP çok iyi hizmet sunuyor ve ürünler bize çok yardımcı oluyor -

S.N. SharmaCHN-TOP makinesi, Çin makineleri için izlenimimi geliştirmeme yardımcı oluyor

S.N. SharmaCHN-TOP makinesi, Çin makineleri için izlenimimi geliştirmeme yardımcı oluyor -

MikeEn iyi fiyata en iyi ürünler, CHN-TOP aferin!

MikeEn iyi fiyata en iyi ürünler, CHN-TOP aferin!

Electrical Conductivity 9.4 X 106 /ohm∙m Vacuum Brazing Paste for Precise and Long-Lasting Joints

| Composition | Silver, Copper, Nickel | Model No | 800-41 |

|---|---|---|---|

| Quality Guarranty | 6 Month | Appearance | Paste |

| Storage Condition | Cool And Dry Place | Form | Paste |

| Shear Strength | 50-80 MPa | Viscosity | 150-200 Pa.s |

| Vurgulamak | high conductivity vacuum brazing paste,vacuum brazing paste for precise joints,long-lasting vacuum brazing paste |

||

Product Description:

Vacuum Brazing Paste is a specialized adhesive designed for brazing PCD/PCBN materials, offering exceptional bonding performance in high-temperature environments. This innovative product is formulated with a precise composition of silver, copper, and nickel, ensuring superior quality and reliability in various industrial applications. The unique properties of this brazing paste make it an ideal choice for joining PCD/PCBN materials with precision and efficiency.

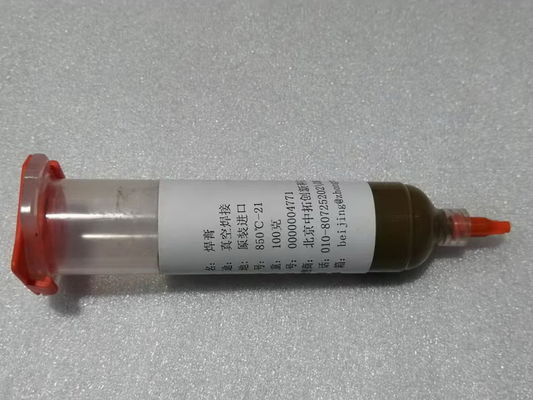

The Vacuum Brazing Paste comes in a convenient paste form, allowing for easy application and precise placement during the brazing process. Its smooth consistency and excellent flow characteristics enable seamless bonding of PCD/PCBN materials with minimal effort. The paste's viscosity ranges from 150 to 200 Pa.s, providing optimal control and coverage for achieving strong, durable bonds.

When handling the Vacuum Brazing Paste, it is essential to store it in a cool and dry place to maintain its effectiveness and prolong its shelf life. Proper storage conditions help preserve the paste's integrity and ensure consistent performance during brazing operations. By following the recommended storage guidelines, users can maximize the product's usability and reliability for their brazing applications.

In terms of appearance, the Vacuum Brazing Paste exhibits a smooth and uniform texture, resembling a typical paste consistency. Its homogeneous composition of silver, copper, and nickel contributes to its distinct appearance and facilitates the brazing process by promoting even distribution and adhesion. The paste's visually appealing and workable form makes it a user-friendly solution for professionals working with PCD/PCBN materials.

Utilizing the Vacuum Brazing Paste for brazing PCD/PCBN materials offers numerous advantages, including high bond strength, excellent thermal conductivity, and resistance to extreme temperatures. The paste serves as a reliable vacuum brazing adhesive that ensures secure and durable joints between PCD/PCBN components, enhancing the overall performance and longevity of the assembled parts. Its compatibility with various materials and substrates makes it a versatile solution for a wide range of industrial brazing applications.

Overall, the Vacuum Brazing Paste is a premium product that meets the demanding requirements of professionals working with PCD/PCBN materials. Its precise composition, convenient form, and exceptional performance make it a top choice for achieving reliable and high-quality brazed joints. Whether used in manufacturing, repair, or maintenance processes, this brazing paste delivers consistent results and ensures the integrity of bonded components. Invest in the Vacuum Brazing Paste today and experience the superior bonding capabilities it offers for your PCD/PCBN brazing needs.

Features:

- Product Name: Vacuum Brazing Paste

- Guarantee: 6 Month

- Electrical Conductivity: 9.4 X 10^6 /ohm∙m

- Composition: Silver, Copper, Nickel

- Viscosity: 150-200 Pa.s

- Temperature Range: 715℃

Applications:

Vacuum Brazing Paste (Model: 800-41) is a specialized adhesive product manufactured by CTSTC, designed for various high-temperature brazing applications. This versatile product is formulated with a composition of Silver, Copper, and Nickel, providing excellent thermal and electrical conductivity essential for brazing processes.

The Vacuum Brazing Paste is suitable for a wide range of application occasions and scenarios due to its exceptional properties. It is commonly used in industries such as aerospace, automotive, electronics, and tool manufacturing. The paste is ideal for bonding carbide materials, making it a preferred choice for brazing applications involving carbide components.

With a viscosity range of 150-200 Pa.s, the Vacuum Brazing Paste offers ease of application and ensures uniform coating on surfaces to be brazed. The product's temperature range of 715℃ makes it perfect for high-temperature brazing processes, providing strong and durable bonds.

CTSTC offers the Vacuum Brazing Paste in syringe packaging, allowing for precise dispensing and easy application. Customers can purchase this product with a minimum order quantity of 10 grams at a negotiable price, making it cost-effective for both small-scale and large-scale manufacturing operations.

For convenience, CTSTC provides a fast delivery time of 5-10 days and flexible payment terms including TT, LC, and Western Union. With a supply ability of 1000 grams per day, customers can rely on consistent availability of the Vacuum Brazing Paste to meet their production needs.

In summary, the Vacuum Brazing Paste by CTSTC is a reliable and efficient solution for various brazing applications, offering high electrical conductivity, temperature resistance, and ease of use. Whether used as a vacuum brazing adhesive, vacuum brazing gel, or brazing paste for carbide, this product delivers superior performance and quality results.

Packing and Shipping:

Product Packaging:

The Vacuum Brazing Paste is carefully packaged in a sealed container to prevent any contamination. The container is labeled with product information, usage instructions, and safety precautions.

Shipping:

For shipping, the Vacuum Brazing Paste is placed in a sturdy box and secured with packaging material to prevent breakage or leakage during transit. The box is labeled with the necessary shipping information and handled with care to ensure safe delivery.